Guiding theme ‘We innovate animal farming’ – 12 to 15 November 2024 in Hanover, Germany – Some 2,000 exhibitors from 55 countries – Robotics and automation in animal husbandry – Animal welfare and benefit to the environment- New FarmRobotix platform at EuroTier 2024 – Barn Robot Event: Feed pusher robot in the dairy housing

Robot-assisted automation for animal husbandry is developing fast with many new applications now available. Farm managers are actively employing these technologies to increase productivity while reducing costs and combating rising shortage of skilled labour. Ultimately this leads to improved working conditions as well as enhanced animal welfare, animal health and benefits to the environment. This ties in with the maxim ‘We innovate animal farming’, the chosen theme for EuroTier 2024 exhibition, which will take place in Hanover, Germany, from 12 to 15 November 2024. Farming professionals will be looking forward to the DLG’s (German Agricultural Society) new platform for robotics, digitalisation, automation and AI in agriculture: FarmRobotix. This time, the Barn Robot Event will focus on feed pusher robots in dairy barns.

Robot-assisted technologies leading to automation in agriculture is developing rapidly. Autonomous, adaptive agricultural systems play an increasing role in practical farming, as skilled labour is becoming scarce. With the help of sensor and electronics, many of these new systems can now assist farms with such a scenario.

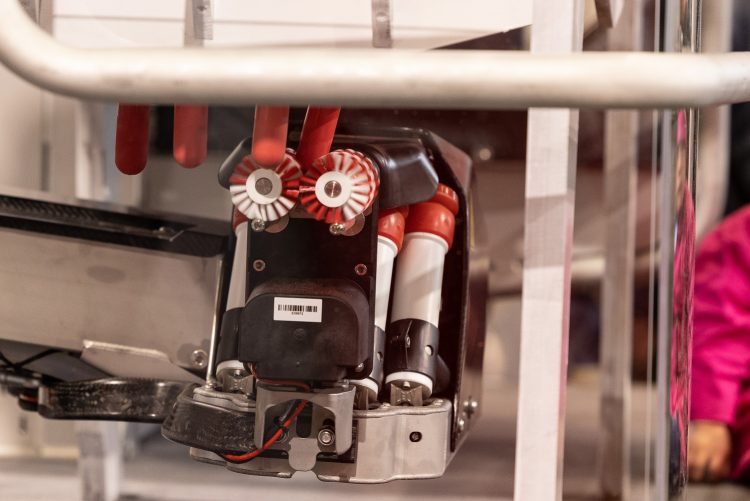

Robotic solutions are increasingly employed in agriculture, including animal husbandry. However, robots for livestock farming can differ significantly from the technologies applied in arable farming. Often the role of robots in animal housing is to improve animal welfare but also to reduce environmental impact, optimise working conditions and ensure profitability.

Major technological advances

Robot technologies in animal husbandry are increasingly used to support the automation of work processes. Compared with robot-assisted systems of the early days, the progress of these advances is significant.

Andreas Pelzer, Head of the Haus Düsse Agricultural Centre of the North Rhine-Westphalia Chamber of Agriculture, believes that any process in livestock farming that can be automated will be automated in the medium term. He compares the development with the mechanisation of agriculture 100 years ago, except that robots are now doing the work. Automation has already existed in animal husbandry for decades, for example in pig feeding. Digitalisation has now brought intelligence to automation. ‘Robots are not just there to automate a process, but also to implement it intelligently,’ emphasises Pelzer.

Advantages for farms

Agricultural businesses can benefit greatly from automating processes with robots. And the benefits increase with each new automotive process that is added.

- One significant factor is improved efficiency and productivity when robots can take on mundane, repetitive tasks that used to take up a significant proportion of farmers’ working time, such as milking, feeding and mucking out.

- Robots free up time that the farmer can spend doing other tasks that previously may have been neglected. This includes intensive animal monitoring and observation.

- Autonomous robots can contribute to improving the quality of life of farm managers and their families and employees. Fixed working hours – early mornings and weekends – may no longer be necessary.

- Farms can increase the number of animals if the farm manager and employees are relieved of time-consuming daily tasks.

- Robots can sometimes help combat the shortage of skilled labour.

Animal welfare and the environment benefit

‘Robotics also offers significant potential in the areas of animal welfare and the environment,’ adds Andreas Pelzer. Being milked by a robot is much less stressful for the cow than being milked by a stressed human,” says Pelzer. She can decide for herself when to be milked and she can find consistent conditions in the milking parlour every day. In bull fattening, the feed provided by robots is much more orientated towards the individual needs of the animals. Interaction with the robot can work to motivate the bulls to move more and, in the best case scenario, can stimulate them to consume more feed. The feed quality is also better, as the feed is always presented fresh.

Pelzer cites robot manure removal as an example of improved environmental impact. The problem with manure scrapers is that they spread piles of manure over a wide area and thus significantly increase the area for ammonia emissions. A floor cleaning robot, on the other hand, can pick up the freshly deposited manure piles in a targeted manner.

Milking robots made the start

Robots have been used in animal husbandry in Germany since the late 1990s. At that time, the first milking robots were adopted in domestic dairy farms. “Milking was a labour-intensive and very complex process that was now automated. Robotic solutions have given farmers many advantages in terms of working hours and quality of life,” emphasises Professor Dr Wolfgang Büscher, Head of the Department of Livestock Farming at the Institute of Agricultural Engineering at the University of Bonn, Germany. Today, following many years of development, the systems work seamlessly and can not only recognise whether the dairy cows are healthy and but can carry out quality control in the background.

In the next wave of mechanisation, automation systems were introduced for feeding, the second largest work position for cows. Professor Büscher: “And we are currently seeing more and more traditional manual work being carried out by robotics. Cleaning robots that move around with the animals in the housing and robots that mix, present and push the feed are still relatively new.”

Robot-assisted systems are also used in pig and poultry farming, albeit to a lesser extent. “The possibilities for using robotics there are limited,” says Andreas Pelzer. However, there are also appropriate solutions for pig and poultry farming, such as litter or washing robots for cleaning pig and poultry houses.

Investment costs often too high for smaller farms

Robotics in livestock farming offers great opportunities. However, the investment costs can be too prohibitive, especially for smaller farms. For example, a milking robot can cost well over 100,000 euros, and the cost of cleaning robots can be in the five-figure range. Such high investments can often only be shouldered by larger farms, with the result that smaller farms lose competitiveness.

FarmRobotix, the new DLG platform for robotics, AI and automation

The DLG (German Agricultural Society) has been focussing on the use of agricultural robots for many years. With its FarmRobotix, the DLG has now created a new platform for robotics, digitalisation, automation and AI in agriculture, which aims to provide knowledge transfer and networking. At EuroTier 2024, FarmRobotix will be presented as exhibits, technical programme and live demonstrations. In addition to daily presentations on the DLG Expert Stage, visitors can experience robots in action on special demo areas and gain practical insights into the operation of autonomous agricultural vehicles and equipment. The Barn Robot Event in Hanover, Germany, will focus on feed pusher robots in cattle barns. In live demonstrations, the robots will show how they can support cattle farmers in practical use on a prepared area.

Find out more about milking robots, the CattleHub trial field of the Bundesanstalt für Landwirtschaft und Ernährung (Federal Office for Agriculture and Food) and expanded professional content here: https://www.eurotier. com/en/programme/we-innovate-animal-farming/robotics-in-animal-husbandry